Carousel small component weighing CSCW

The perfect combination – manual precision meets intelligent control

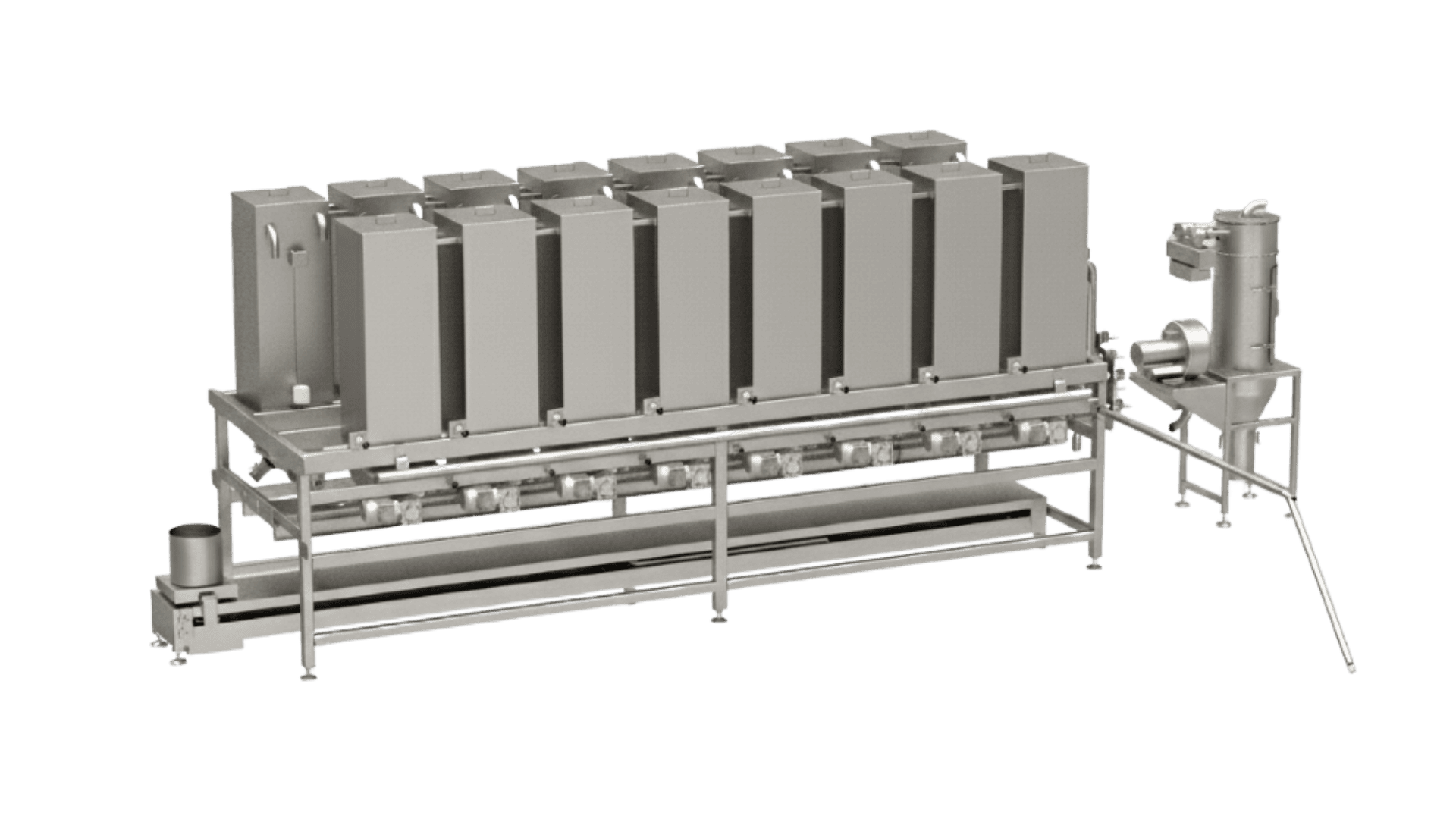

The semi-automatic small component weighing system CSCW (Carousel Small Components Weighing) is used for manual weighing of granular or powdery bulk materials with different bulk densities and flow characteristics. It is also used for providing bulk material batches, particularly for the production of rubber blends. The CSCW system features a rotary carousel with carrier containers and an integrated rotary bucket scale. This enables precise and reliable recipe-controlled dosing of small components. For this purpose, the CSCW system can be moved in front of a linear frame with bulk material storage hoppers. The operator manually doses the bulk materials into the rotary bucket scale, which empties into the bag inserted into the corresponding carrier container with a 180° rotation after reaching the target weight. An aspiration system reduces cleaning effort and ensures improved occupational safety and environmental protection during the weighing and emptying process. In this way, several batches can be prepared, and the bags can then be removed from the rotary carousel and replaced with new bags.

Safe dosing of small components

- Inexpensive, semi-automatic dosing system

- Compact design

- High weighing accuracy

- Recipe-controlled dosing

- Aspiration during the weighing and emptying process

Safety in every aspect

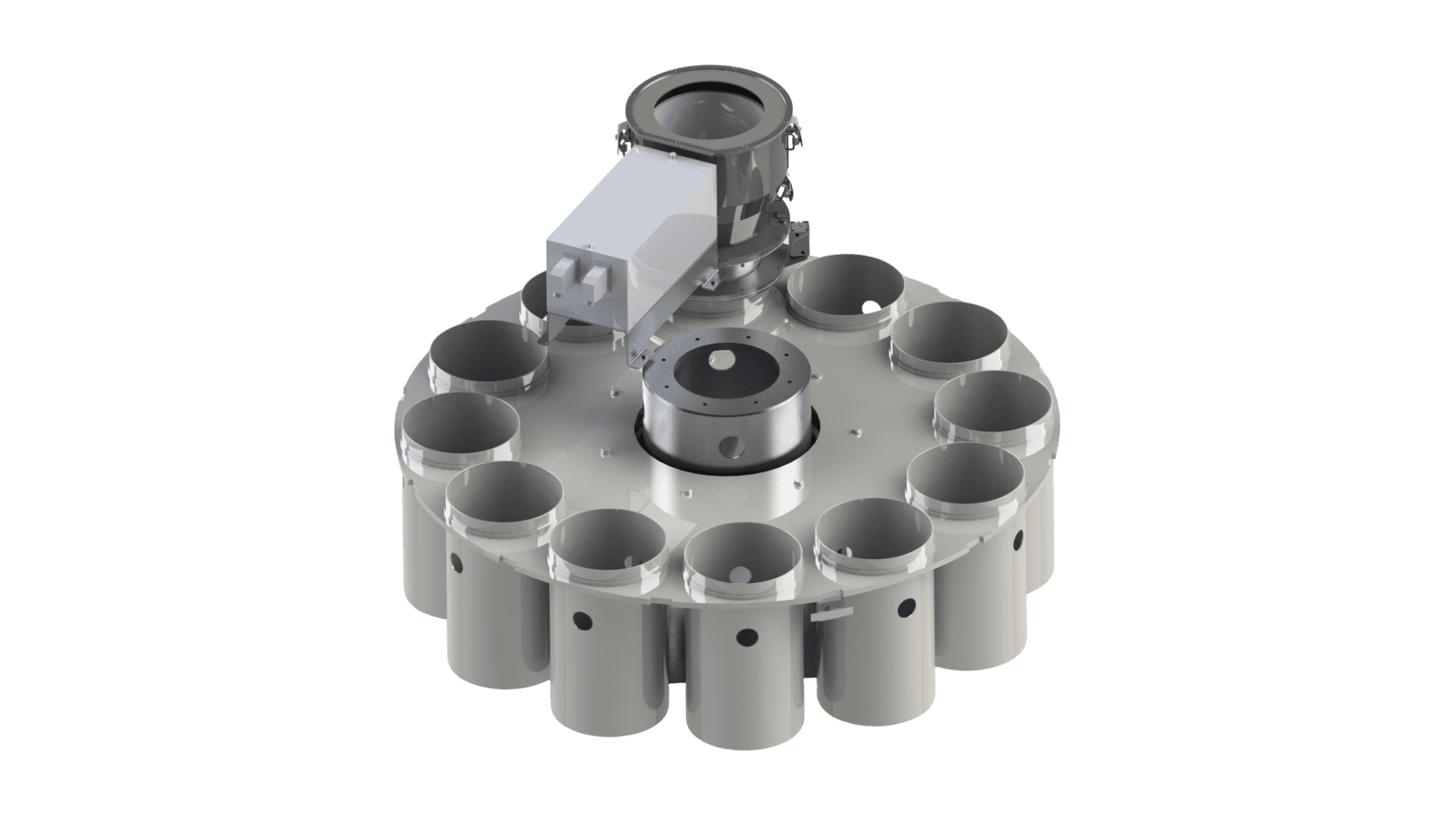

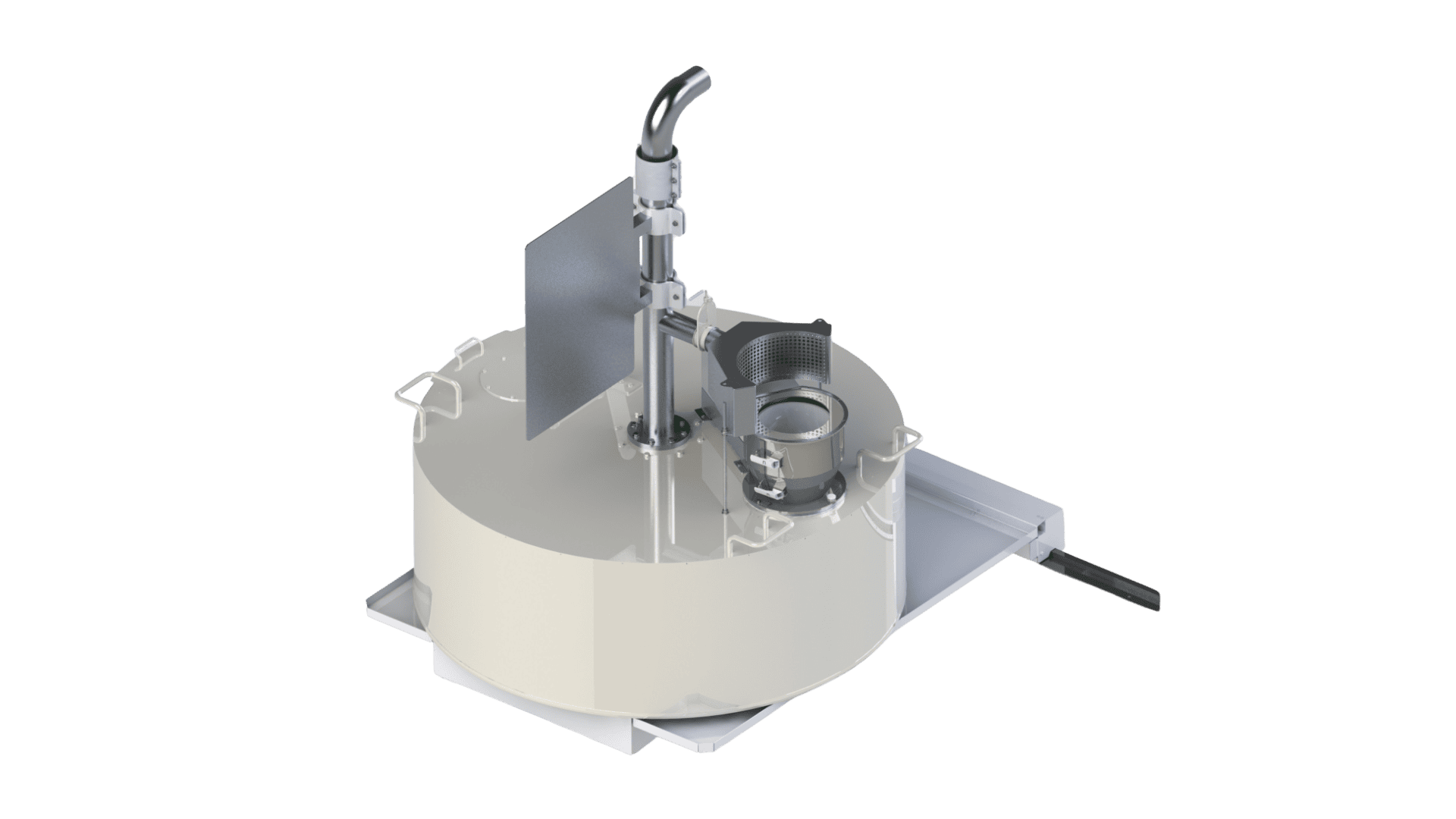

The system consists of a mobile frame with a tray and rollers for rail-guided movement. A motorized carousel with container holders accommodates twelve carrier containers (20 liters each). The 180° rotatable container scale (10 kg/25 kg) has an aspiration hood for low-dust dosing and emptying of the weighing container into the carrier container. A connection nozzle for central aspiration is also provided. Side covers and a carousel cover with a transfer opening have proven effective in practical use.

The discharge flap is equipped with a safety limit switch and viewing window. Additional limit switches monitor the weighing and discharge positions. The HMI is integrated into the control cabinet, along with an emergency stop button.

Product advantages

Performance

The use of automated weighing systems achieves a significantly higher performance increase compared to purely manual weighing. This allows processing of up to 30 batches per hour, which enables a considerable increase in efficiency and time savings in the production process.

Flexibility

The movable dosing system offers maximum flexibility in production. Thanks to its modular design, an unlimited number of components can be processed, allowing the system to be individually adapted to various recipes and production requirements.

Quality

Manual weighing ensures high precision in component dosing. Even the smallest quantities can be measured accurately, guaranteeing the highest quality standards throughout the production process.

Service-friendly

The system is characterized by low cleaning requirements, which significantly simplifies maintenance and minimizes downtime. It also impresses with its easy installation and commissioning, enabling quick and seamless integration into existing production workflows

Key facts at a glance

Dosing performance

Up to 30 batches per hour with maximum flexibility thanks to the ability to process an unlimited variety of bulk materials. Up to 12 identical batches can be processed per cycle – fast, precise, and consistent in quality.

Sizes

Rotary carousel with 12 carrier containers (20 l), rotary bucket scale (10, 25 kg).

Application

Manual recipe-controlled dosing of granular or powdery bulk materials.

Pressure

Pressureless

Weighing range

10 kg – 25 kg

Temperature

From 10 bis 40 °C

Materials

Parts in contact with the product are corrosion-resistant.

Advantages for the industry

Chemistry

There are countless recipes and concepts for the production, processing, and recycling of plastics. With us by your side, you ensure that they always become successful recipes and concepts. We offer the full range of plastic plants, from process, mixing, and storage silos to conveyor systems, key components, and cleaning systems. What sets our plants apart: full flexibility, decades of expertise, patented process solutions, and a globally networked industry specialist.

Go to chemistry

Plastics

When it comes to introducing difficult-to-process raw materials and substances into the production process in a gentle, precise, and timely manner, in the correct sequence and with exact dosing, Zeppelin’s solutions for the production and compounding of engineering plastics, PTA/PET, battery materials, specialty chemicals, and paints are the right choice. We not only offer tailored plant concepts but also have the expertise to develop optimal solutions.

Go to plastics industry

Rubber & Tire

Worldwide, we have already completed over 500 projects for the rubber and tire industry – from individual silos to fully turnkey plants. Our well-designed solutions provide measurable advantages across the entire value chain, all the way to recycling. We consistently focus on excellence in terms of material selection, technology, durability, and service.

Go to rubber & tire industryWant more details? Our contact persons will be happy to help you.

Related products

Complementary products for an optimized process chain

KOKEISL Discharge and Dosing Module

Reliable discharge and precise dosing become effortless with the mechanical discharge and dosing module KOKEISL. A wide variety of bulk materials can be transferred in any quantity with extremely high throughput accuracy from silos and containers into other vessels.

Go to Discharge Modules

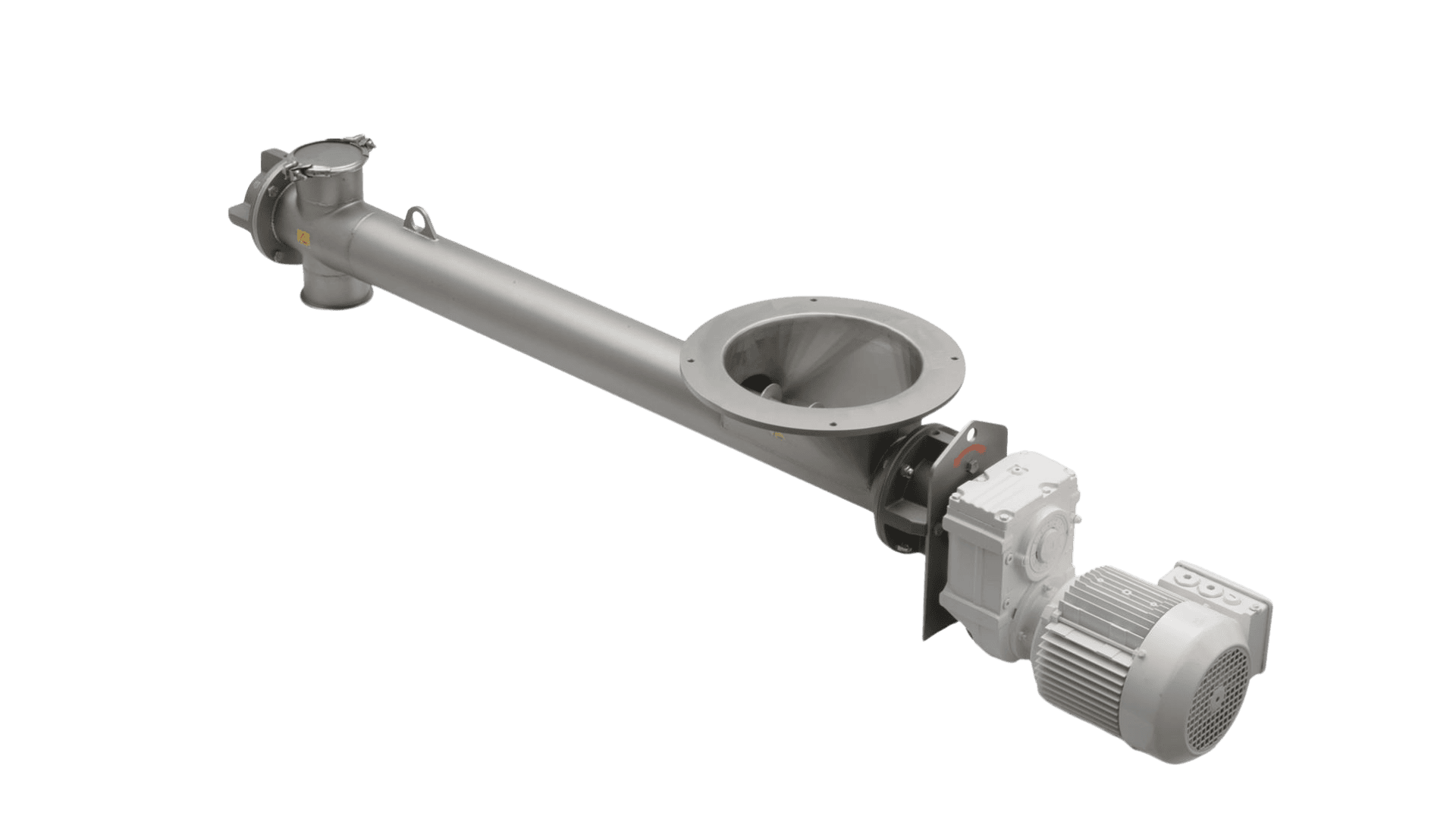

Dosing and Conveying Screws

When it comes to the smooth dosing of dry, powdery, and granular bulk materials, our dosing and conveying screws come into play.

Go to Dosing & Conveying Screws

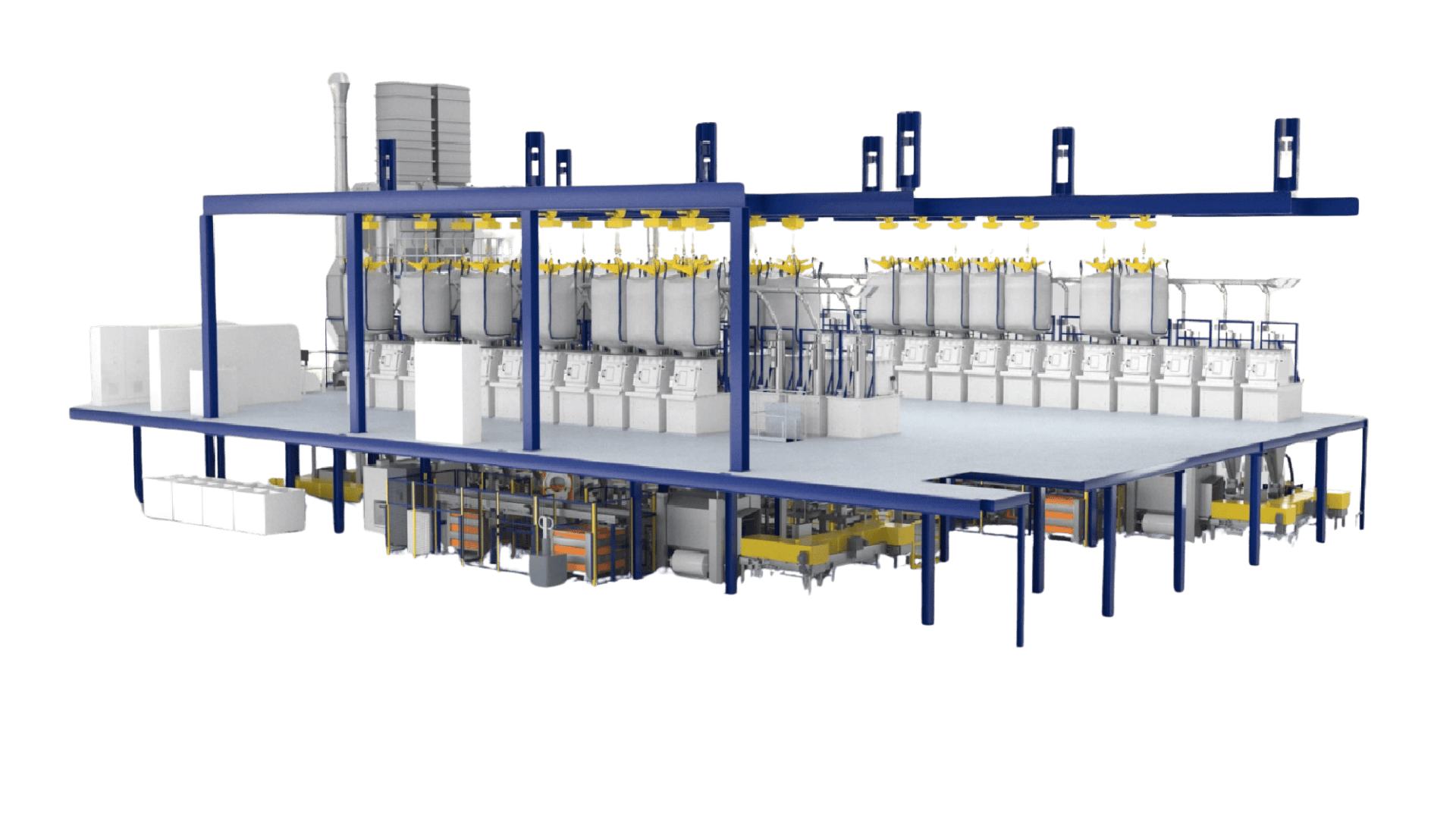

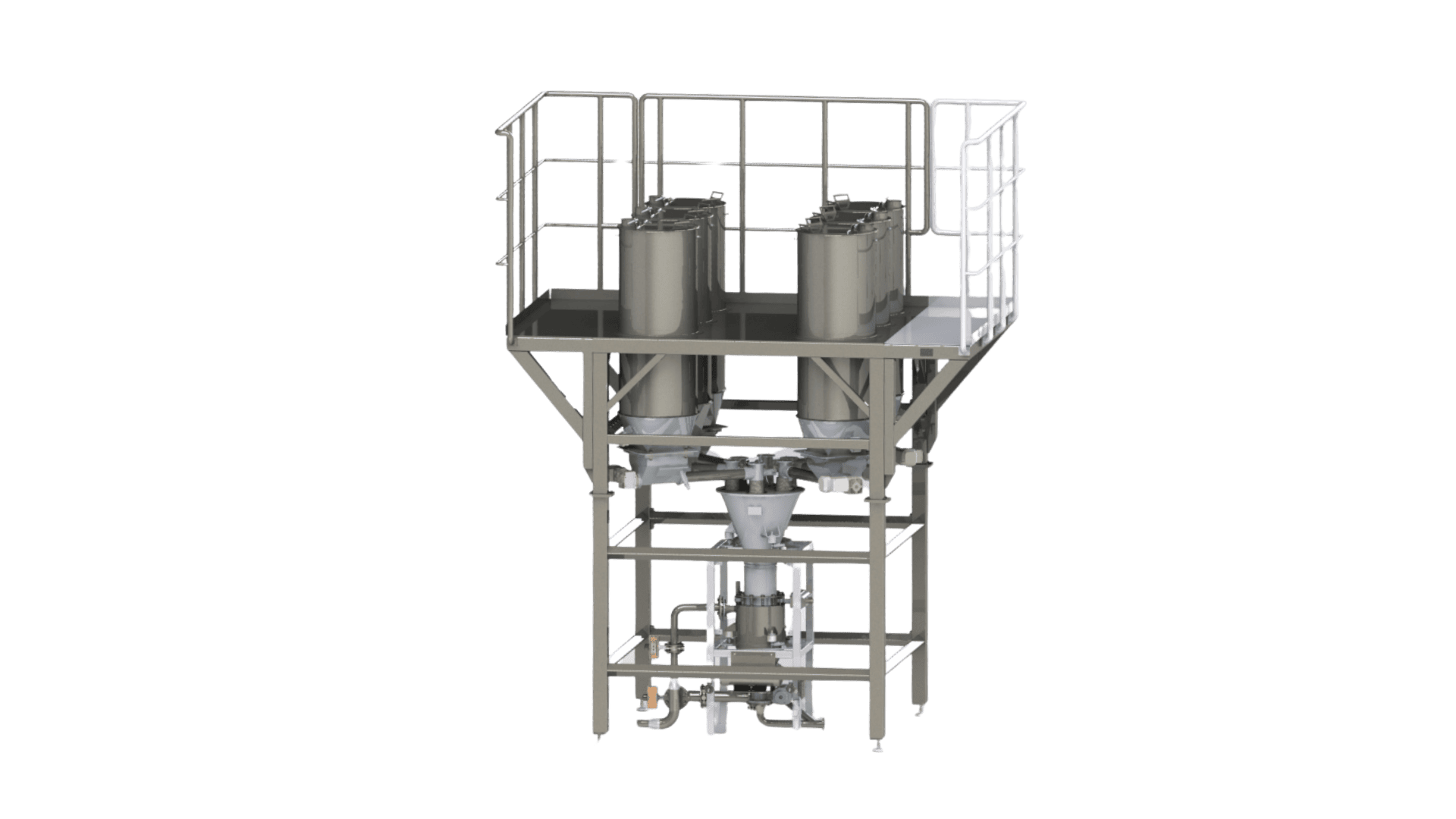

ASCW Automatic Small Components Weighing System

The ASCW (Automatic Small Components Weighing System) automatically doses and weighs granular or powdered bulk materials with different bulk densities and flow properties. The system also prepares bulk material batches that are required in particular for the production of rubber compounds.

Zum ASCW

MicDos small component weighing

The MicDos (Micro Ingredients Dosing System) small component dosing system automates the handling of bulk ingredients in the food, chemical, and pharmaceutical industries. The system is suitable for storing, sequentially dosing, and accurately weighing up to 20 free-flowing to heavy-flowing bulk materials.

To Micdos

MinDos small component weighing

The MinDos (Minor Ingredients Dosing System) small component dosing system is mainly used in the food industry, where the trend is towards industrial-scale ingredient systems integrated into fully automated large-scale plants.

Zu Mindos

Flexible Container Scale HSF

The flexible hopper scale HSF is primarily used for fully automatic weighing of powdered bulk materials such as carbon black and silica, but it is also a good choice for granules.

Go to Flexible Container ScaleOur Customer Services for You at a Glance

Show all Customer ServicesEurope

Zeppelin Systems Benelux N.V.

Zeppelin Systems France SARL

Zeppelin Systems GmbH - Zentrale

Zeppelin Systems GmbH Food Processing Plants

Zeppelin Systems GmbH Niederlassung Freital

Zeppelin Systems GmbH Mixing Technology - Kassel

Zeppelin Systems GmbH Mixing Technology - Detmold

Zeppelin Systems Italy S.p.a.

Food + Polyolefine

Zeppelin Systems Italy S.p.a.

Rubber + Spareparts

Ressourcen

Brochures for download

© 2025 Zeppelin Systems GmbH